• Resin sand process

• Production capacity: 25,000 tons/year...

>100 tons

30-100 tons

<30 tons

Rapid Prototype

CT 9-11

CT 8-10

CT 7-8

0.5-8 tons

0.1-1.2 tons

1-300kg

Mechanical properties

Mechanical properties

Size requirements

Size requirements

Appearance quality

Appearance quality

Internal defects

Internal defects

Chemical composition

Chemical composition

Microstructure

Microstructure

Smooth filling

Smooth filling

No shrinkage risk in critical areas

No shrinkage risk in critical areas

Appropriate output rate

Appropriate output rate

Sand iron ratio is suitable

Sand iron ratio is suitable

Production efficiency meets batch delivery

Production efficiency meets batch delivery

Mechanical properties

Mechanical properties

Size requirements

Size requirements

Appearance quality

Appearance quality

Internal defects

Internal defects

Chemical composition

Chemical composition

Microstructure

Microstructure

Founded in 1981, e-Traction is the world's leading R&D and production enterprise of in-wheel motors and electric vehicle transmission systems, with more than 200 patented technologies.

In order to improve the vehicle efficiency and economic benefits of medium and large commercial vehicles such as buses and promote transportation innovation, e-Traction has developed a new generation of in-wheel motors (TheMotion 2.0). During the research and development process, the development team followed the energy transfer rules of the technical system, shortened the length of the energy flow path, and significantly reduced the energy loss in the process of transferring electrical energy to the wheels. e-Traction’s direct-drive hub motor power technology not only improves energy transfer efficiency by 15% compared to industry benchmarks, but also reduces operating and maintenance costs and operating noise by reducing the number of moving parts. At present, many overseas bus companies have adopted e-Traction’s in-wheel motors.

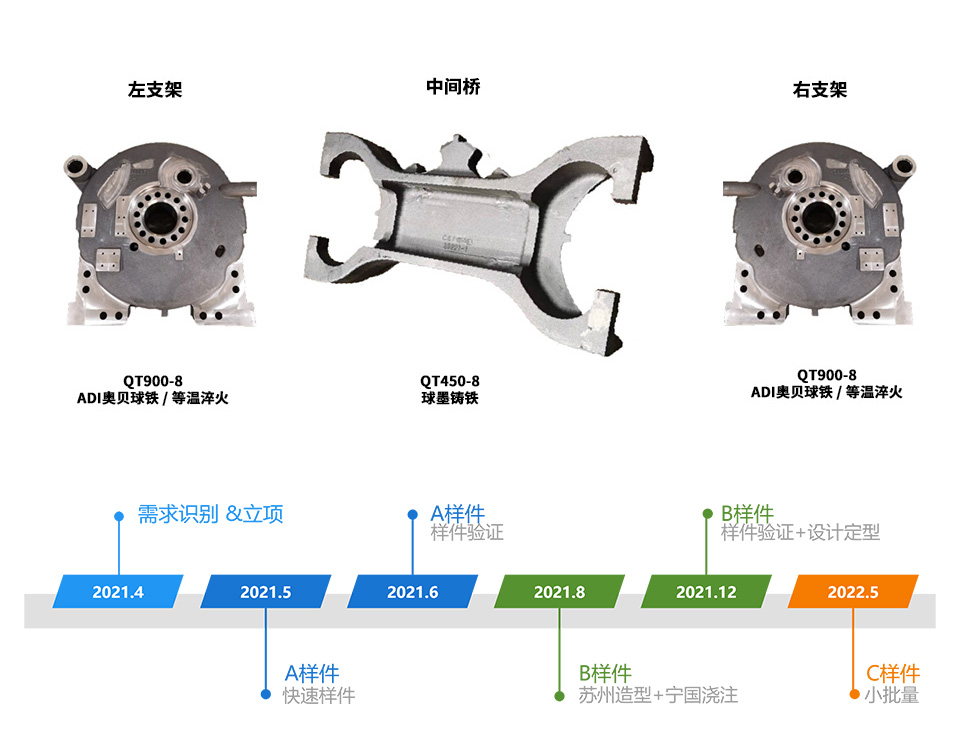

During the development process of the in-wheel motor, e-Traction chose to jointly develop the in-wheel drive axle with the Casteks team. The drive axle consists of a middle axle and left and right brackets as the main body.

After the project started, the Casteks project team confirmed with the customer the usage environment, durability and performance requirements of the wheel hub drive axle. The left and right brackets support the load of the entire vehicle and absorb vibrations from the ground. The material requirements reach QT900-8 and need to pass ADI material castings are obtained by isothermal quenching. With its expertise in castings and casting processes, the Casteks team assists the e-Traction design team in optimizing the drive axle structure based on data-based decision-making through castability analysis, casting filling, solidification and casting stress analysis. Samples, B samples and C samples were delivered with quality and quantity at all stages, achieving a win-win situation with customers.

This cooperation not only helps e-Traction promote the innovation of transportation, but also provides Casteks with an opportunity to demonstrate its integrated one-stop full-process casting service. In the future, Casteks and e-Traction will have more cooperation possibilities and jointly contribute to the development of new drive technology.

(Picture 1 is from Drive Vision. If there is any infringement, please contact us to delete it)

Platform Information Submission-Privacy Agreement

· Privacy Policy

No content yet