Learn more

Casting Observation: Why did the Japanese electrical giant choose Casteks? Three core advantages lay the foundation for cooperation

Time: 2024-08-22Source: View: 275

There is a saying in the Japanese electrical industry: "Wherever there is electricity, there is Meidensha." As one of the five largest electrical manufacturers in Japan, Meidensha's products are distributed in every corner of society, from power generation equipment, transformers to elevator drive systems and power safety systems. They can be found everywhere.

The MEIDEN Group was founded in 1897 and has dozens of subsidiaries in China and abroad. The MEIDEN Group's slogan is "Quality connecting the next", where "quality" refers not only to the quality of products and services, but also to the "people" and "technology" that support them. MEIDEN has a lofty goal, which is to establish stronger ties with customers around the world through the honesty and flexibility of its employees, and to contribute to society by providing unique products and reliable services through technological capabilities that adapt to the times and markets. Guided by this philosophy, the Meidensha Group grows together with society, aims to become a "company needed by society", constantly accepts challenges, and creates new technologies and new value. ![]()

The beginning of fate

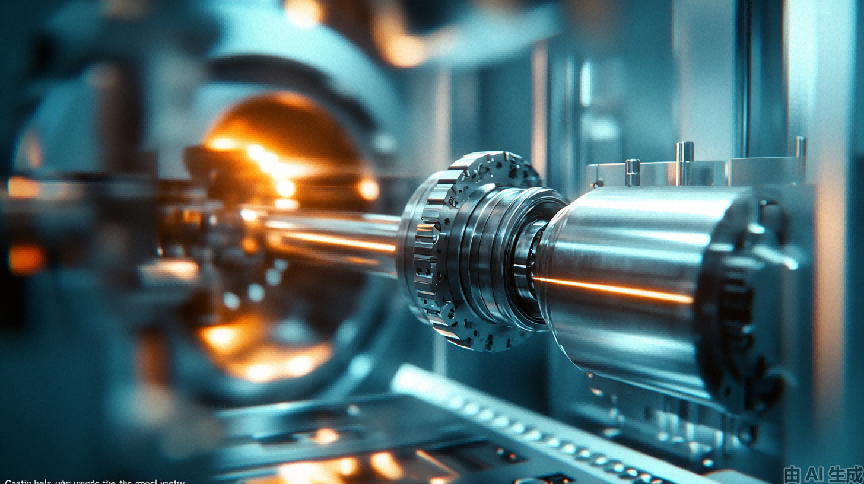

Kaishi Iron and Mingdianshe met in 2020 and have been cooperating for more than four years. The products we cooperate with Mingdianshe are mainly elevator traction sheaves. Considering that the traction sheave has a relatively high hardness requirement (279HB~321HB), we finally chose the iron mold sand coating process, which can meet the requirements directly in the casting state, eliminating a normalizing process. In addition, the hardness uniformity of the traction sheave is very high. We paid special attention to it at the beginning of the design, and the final product can achieve a single piece hardness difference of no more than 20HB.

Think twice

When Mingdiansha was looking for a traction sheave casting supplier, it visited many professional foundries, and Kaishi Iron was just one of them. What made Kaishi Iron stand out from the candidate list?

1.Rich casting and machining experience

Before cooperating with Mingdianshe, Kaishi Iron had already cast parts for elevators and related equipment for many brands and accumulated a lot of experience. These experiences can help both parties reach a consensus in the design, development and production of products such as traction wheels, and reduce the time and material cost losses caused by ineffective communication.

In addition to the casting process, Kaishitie also has rich experience and mature equipment system in casting machining, which can meet Mingdianshe's requirements for subsequent machining of castings and facilitate the entire casting delivery process. When the Mingdianshe team visited Kaishitie's factory, they had an in-depth understanding of the machining process and were very interested in our hoisting fixtures and protective tooling for spray painting, and said that these were worthy of their internal reference and study.

2.Communicate at the same frequency, customers first

Kaishitel's management team is composed of a group of team members who have served in senior management of leading companies in various industries around the world. They have international thinking and perspectives, can communicate at the same frequency with customers from different countries and regions, understand the casting needs of different industries, and reduce the risks of communication misunderstandings from the source.

Kaishi Iron's Shatka Technology (Jiangsu) Co., Ltd. has three Japanese shareholders - Sodick, Towa, and KGK Kanematsu. This helps Kaishi Iron to obtain a more accurate understanding of the needs of Japanese customers on another level, and to provide more timely feedback to Japanese customers' opinions.

Kaishi Iron has summarized five major organizational capabilities, among which "user orientation" ranks first. It is this emphasis on users that has made Kaishi Iron gain unanimous recognition from its cooperative customers and established a good reputation at home and abroad.

Three,Professional project development and management process

Kaishi Iron has always been committed to building a modern casting system, introducing advanced management systems and casting production equipment, and can provide customers with full supply chain integrated, one-stop casting services from casting production, heat treatment to machining, and equipped with professional production quality supervision software and hardware.

Kaishi Iron has always been committed to building a modern casting system, introducing advanced management systems and casting production equipment, and can provide customers with full supply chain integrated, one-stop casting services from casting production, heat treatment to machining, and equipped with professional production quality supervision software and hardware.

Before the cooperation, Mingdianshe sent a corresponding team to inspect, led by the deputy general manager in charge of technical quality, and combined internal production management and quality supervision.

During the inspection, the Mingdianshe team visited the entire production process and was very impressed by our smelting process control. They discussed with our technical staff on the aspects of pouring time control and the use of in-stream inoculation. After this inspection, Mingdianshe finally decided to cooperate with Kaishitie.

In-depth cooperation

In 2024, after several years of cooperation, Kaishitie and Mingdianshe have established mutual trust. Therefore, when Mingdianshe was considering re-opening molds for other products, it thought of us, Kaishitie, and soon signed a development agreement with us for 11 products, covering resin sand and coated sand shell processes.

In the future, Kaishi Iron will continue to work hard to improve the level of customer service while innovating casting technology and digital transformation, live up to the trust of customers, and prove with actions and castings: If you want castings, look for Kaishi Iron!

-

Walking into the Casteks casting factory , they actually do these2024-09-12

-

Casting helps upgrade the "heart" of industry - what has Casteks done for the development of Suzhou's industrial mother machine industry?2024-09-05

-

Warm congratulations to STK Technology (Jiangsu) Co., Ltd. for being included in the second batch of "Standardized Conditions for Foundry Enterprises" list of qualified enterprises of China Foundry Association2024-09-03

-

Casteks Metal Technology (Jiangsu) Co., Ltd. officially joined the Jiangsu Foundry Association2024-08-22

-

Casting Observation: Why did the Japanese electrical giant choose Casteks? Three core advantages lay the foundation for cooperation2024-08-22