Learn more

Walking into the Casteks casting factory , they actually do these

Time: 2024-09-12Source: View: 265

Castings are the link between foundry companies and customers, and their quality directly affects the trust and depth of cooperation between companies and customers. As the front line of casting production, foundries have undoubtedly become the key control of casting quality, requiring foundries to devote energy to multiple links, and Casteks is doing just that.

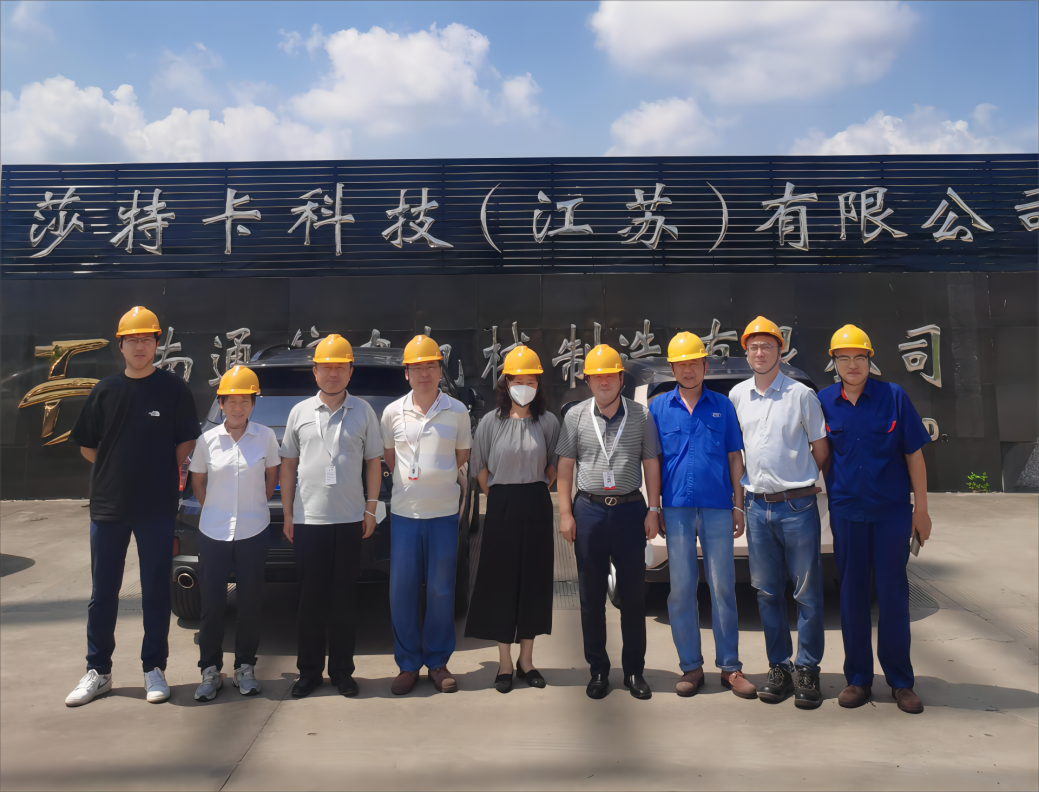

I believe everyone is very curious about Casteks factories. Let's follow us today to Hai'an Factory, one of Casteks three factories, to see what Casteks foundry people do every day.

The defense behind the casting——The quality inspection link of the laboratory

The first stop of the visit was the production area of the Casteks Hai'an factory. In addition to the production workshop, the most conspicuous thing was the label on the side that said "CSTKLaboratory" room. Following the footsteps of physical and chemical inspector Cheng Limin, we walked into the laboratory. What caught our eyes were various instruments neatly placed on both sides of the room. These instruments had different shapes, which made us laymen confused for a while. Cheng Limin briefly introduced the functions of these instruments to us. From the sand strength machine for testing the compressive and tensile strength of the molding sand to the Brinell hardness machine for testing the hardness of the castings, the equipment here covers the testing process from raw materials to castings, which is quite complete.

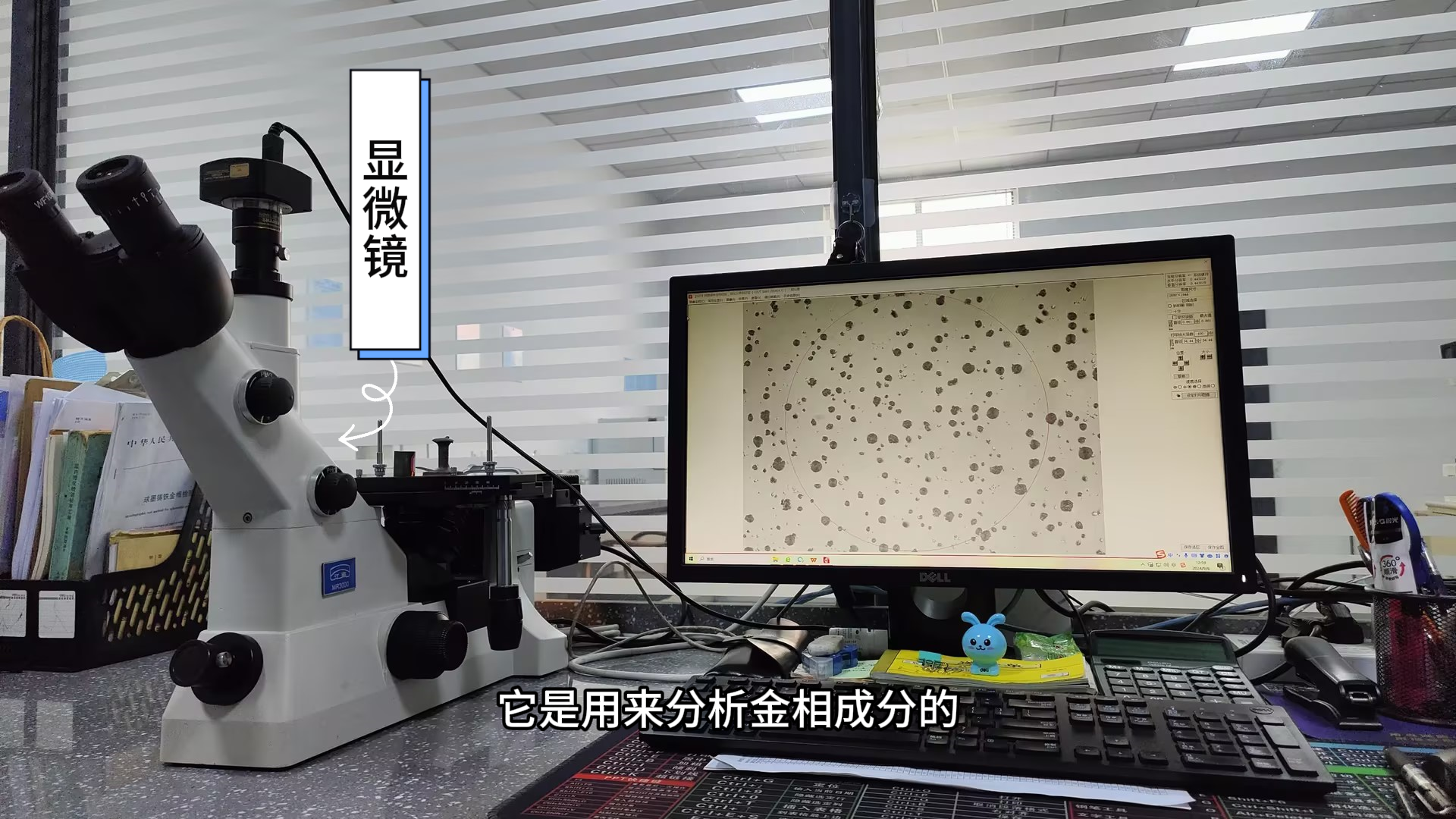

At this time, Cheng Limin took us into a separate room in the laboratory. It turned out that there were several testing equipment here, mainly used for metallographic inspection. The microscope placed next to the computer is the core of metallographic inspection. Not far away is the metallographic experimental polishing machine, which plays a very important role in the preparation of metallographic specimens. "The preparation of metallographic samples has a strict process, which is carried out in the order of sampling - coarse grinding - fine grinding - polishing," Cheng Limin introduced to us the precautions in metallographic samples, "The purpose of polishing is to remove the grinding marks on the grinding surface of the sample, making it bright and traceless, and achieving a mirror-like effect."

The first impression the laboratory gave us was professionalism, followed by cleanliness and tidiness. The laboratory's equipment maintenance and environmental management are quite good. In this environment, the results of various tests are believed to be accurate and convincing.

The laboratory's quality inspection will check the quality of the raw materials and the castings themselves. This set of inspection procedures throughout the entire casting process will be a solid line of defense behind the casting, which can reduce the defect rate of the final castings, improve the quality of the castings, and make customers more assured.

Before departure"Close seams"-Preparation before castings are shipped

After leaving the laboratory, we went to the inventory area and found that a batch of castings were about to be shipped to customers, so we stopped and prepared to take a look at the tools used when loading castings. But unexpectedly, the on-site operators did not immediately use the overhead crane, but began to clean the surface of the castings.

"We clean the surface of the castings before loading them. You may see that there is nothing on the surface, but there are still some dust and dirt on them," Li Pengfei, the administrator responsible for the shipment of castings, explained to us, "After cleaning the surface, we will review the quality of the castings."

After completing the surface cleaning of the castings, the quality of the castings was reviewed on site, and the outside and inside of the castings were carefully checked. In addition to the naked eye and touch inspection, a non-destructive flaw detector was also used for more in-depth testing.

All inspections were correct, and the operator carefully sent the castings one by one to the truck with a crane, and then carried out a series of stabilization and packaging work on the castings, wrapping them tightly. It rained today, and such packaging makes people feel at ease.

The delivery of castings is an important part of casting services. If there is an error in the delivery process, the casting products cannot be delivered to customers on time and with quality, and the entire cooperation will face the risk of breaking down.

In Casteks operation and decision-making principles,safety, quality, deliverywas listed in the top three, which is enough to prove that Casteks attaches great importance to the quality of castings and the entire process of casting services. We always believe that a rigorous attitude can bring good casting products, and good products can win the trust of customers. Through satisfactory full-process services, this trust will be more solid and longer-lasting.

If you want to know more about Casteks and the factory, please follow our video account: Casteks Casting Factory. We will continue to update the content and take you to visit every corner of the Casteks Factory online.

-

Walking into the Casteks casting factory , they actually do these2024-09-12

-

Casting helps upgrade the "heart" of industry - what has Casteks done for the development of Suzhou's industrial mother machine industry?2024-09-05

-

Warm congratulations to STK Technology (Jiangsu) Co., Ltd. for being included in the second batch of "Standardized Conditions for Foundry Enterprises" list of qualified enterprises of China Foundry Association2024-09-03

-

Casteks Metal Technology (Jiangsu) Co., Ltd. officially joined the Jiangsu Foundry Association2024-08-22

-

Casting Observation: Why did the Japanese electrical giant choose Casteks? Three core advantages lay the foundation for cooperation2024-08-22